Custom Magnet Wire Coils MANUFACTURE

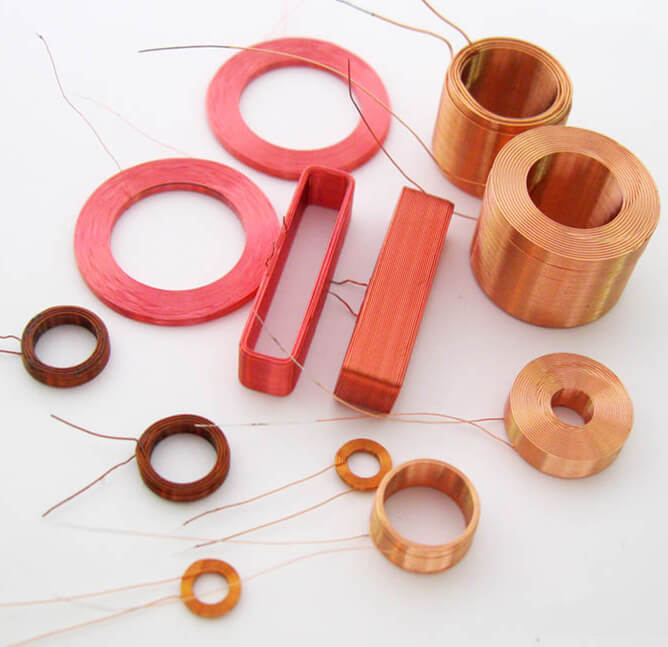

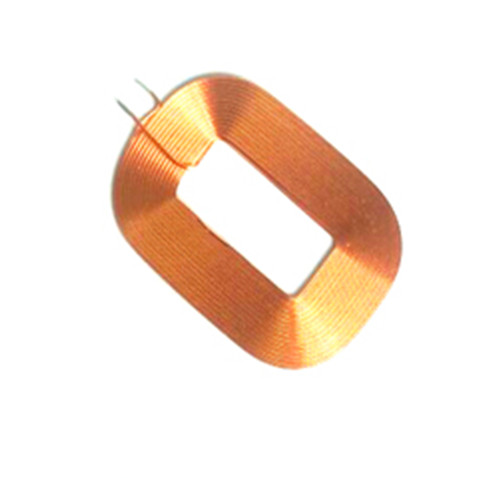

JHCOILS is a professional magnet wire coil manufacturer, who supplies different kind of coils to different kind of industry as above. JHCOILS also accept custom air coil winding, the magnet wire coil can be made in Square, Oral, Round, special shape according to customer requirement.

Making use of our high-quality wire, JHCOILS is able to create high standard custom coils for your application.

What is the Magnet Wire Coils

As the name shows, the magnet wire coil is a coil that formed by magnet wire. Each turns of magnet wire is in the winding coil is insulated, so When current flows through the wire, a magnetic field can be generated around the coil. The strength of the magnetic field is proportional to the current flowing through the coil and the number of turns of the coil. Similarly, in a certain magnetic field, using a coil to cut the magnetic lines of force, the magnetic field can also generate electrical energy. Using this principle, it can be made into relays, motors, wireless devices, horns, etc.

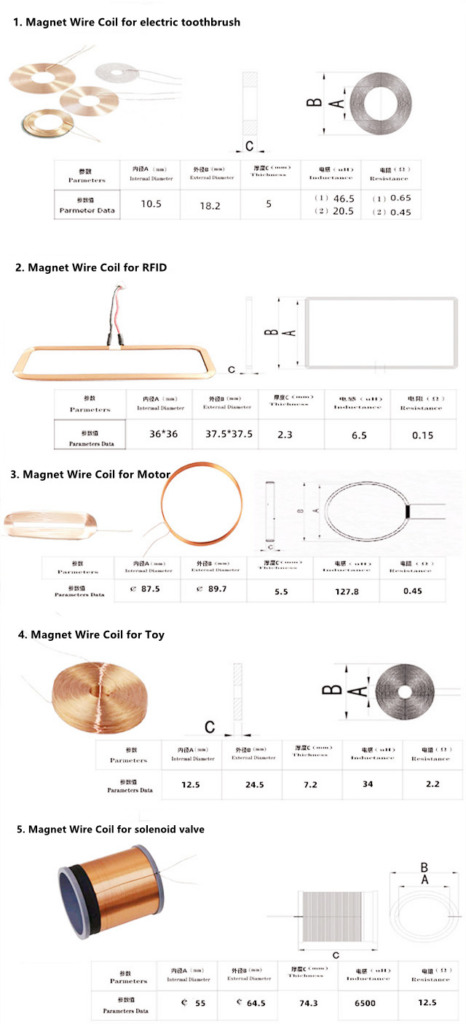

Application Magnet Wire Coils

One of magnet copper wire used in air coil winding is called Self-bonding enamelled wire, Which means except of internal insulation layer, it also has a bonding layer as the outside periphery. This kind of magnet wire is allow coils to be adhered by heating or applying solvent during or after coil winding. This magnet wire air coil is widely used in RFID, Wireless Charging, NFC, IR Switch for Camera, Coin Collector machine, Motor.

Magnet wire coil for coin collection machine

Magnet wire coil for IR cut camera

Magnet wire coil for night light

Magnet wire coil for wireless charging

Features of Our Custom Wound Air Core Coils

Various structures meet customer’s specifications

Wide inductance range

Good for high-frequency applications

Good for high-temperature condition

Multi-layer structure

Self-bondable wires available

Operating temperature: -50 to 220 degrees Celsius

Wire diameter range: 0.02 to 1.2mm

The shared AWG winding wire gauge chart below is based off bare-no film wires. We also create wire coils and shapes using coated wire. Contact us to find out more.

TOP QUALITY

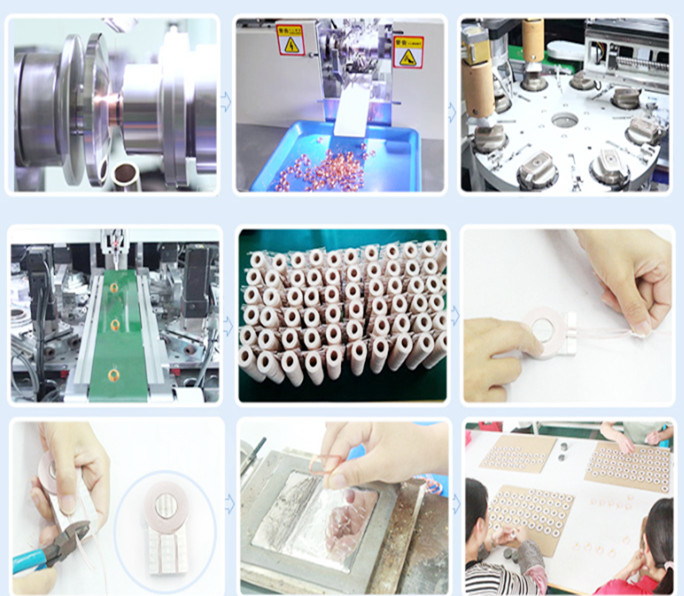

ISO quality management certified factory, complete quality inspection process in production process, dimensions measuring, appearance check, performance and other multi-faceted supervision, and all of material used in the coil assembling meet ROHS environmental protection standards.

Production of Custom magnet wire coils

Most of our air coils are made by high precision auto CNC winding machine, which can better confirm the tolerance of coil specific like coil size and inductance requirement.

We are proud to use our coil winding expertise and wire winding technology to provide high-quality solutions to your electromagnetic coil needs.

Here belows you can check the specific of our magnet wire for your coils design.

All shapes, sizes and custom coil assemblies replacement

Whether you need to shrink type or different kind of connector wire to the custom coil assemblies for your further better easy assembling work, we will try our best to meet your requirement. We will also choose right degree of Self-bonding enameled round wires based on your industry application. Except for the custom air core coils for you, We can design from bobbin scratch or manufacture an induction ferrite coil replacements.

We can customize an air core coil to meet the number of turns, the conductor type, and the inductance specification to best match your application requirements.